There are two types of glued panels. What’s the difference?

This is the first question for anyone who has discovered the world of solid wood and furniture board. The two types of board differ in price and appearance. But most importantly, they differ in configuration. We will take a detailed look at the differences and what type of panel is better to use in your particular case.

Fingerjoint: Your Reliable Support In The Kitchen

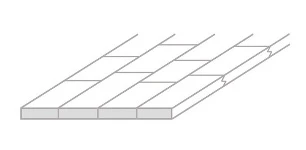

Fingerjoint panel consists of short lamellas (lamella isa board planned from all sides). The lamellas are glued to each other by 4 sides.

The length of lamellas is usually from 200 to 500 mm. The width of lamellas are of two types:

A) narrow, 20 mm width

Thus, you get a mottled narrow lamella board.

Such a small size of the workpiece allows using any residual wood for woodworking manufacture. Even though there is a lot of work to glue all the small items together, still, this is the cheapest type of panels.

B) standard, 40-50 mm width

A standard fingerjoint panel looks like parquet. It isnot as homogeneous as edge glued panel. However, it has its own advantages. One of the rules of woodworking is that the more glues, the more reliable the product. The number of gluings in fingerjoint panels is several times higher than in edge glued. So fingerjoint panels are a great decision for kitchen tabletops, where there is a high exploitation level. On the comparison, fingerjoint panels don’t look as organic as an edge glued panelin case of its use as staircase steps.

The price for 1 m3 of fingerjoint panel does not change depending on the length. For a manufacturer, it is insignificant, whether the panel is 2m or 4m long. The reason being, fingerjoint panels usually use those lamellas, that were too short for edge glued panels.

Edge glued panels are the right choice for stairs and long expensive tabletops

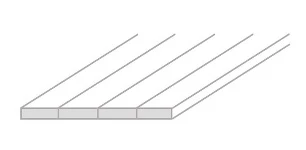

The edge glued panels consist of long lamellas (4 sides planned boards). The lamellas are glued to each other by 2 sides. The length of the lamellas is equal to the length of the panels, and is limited only by the availability of raw materials. As in the previous case, here we can also classify all the panels into two types according to the lamella width:

A) standard, 40-50 mm

B) wide, >50 mm

Wide lamellas are usually in the range of 60-70 mm, 80-90 mm, 100-120 mm. The wider the lamella, the more "natural" the panel will look and the more it will remind us of the typical wood structure we imagine. However, at the same time it makes the panel less resistant to deformation. When working with a wide lamella panel, you need to be clear about all the possible difficulties. For example, if you have a tabletop on minimalist metal legs, it is recommended, of course, to reinforce the tabletop at the bottom with a metal clamp.

The price for edge glued panels depends on their length. The longer the panelis, the higher its unit price per cubic meter. This is due to the complexity of making long lamellas. They require large amounts of selected raw material, without defects and knots. Such tree trunks are rare, so they are expensive.

The field of application of such a panel knows no limits. Tabletops, window sills, décor - you can make anything out of it. We should also highlight the stairs. Steps made of edge glued wood are a real classic.